Plastic bottle cap mold casting system planning: According to the layout of the plastic part, the mold is planned as a three-plate type with point gates, which are set in the center of the top of the plastic parts; point gates can significantly increase the shear rate of the melt and make the melt A large decrease in body viscosity is conducive to mold filling. Moreover, as a packaging container, plastic parts require high appearance quality, and the residual traces of the point gate are small, which can ensure the surface quality of the plastic parts; when demolding, the gate is actively broken, which facilitates the automation of the product production process and improves Increased production power and increased economic benefits. If you want to know more about plastic bottle caps, you can consult Taizhou Huangyan Yongsheng Mould Industry Co., Ltd. online, and we will serve you wholeheartedly. The pros and cons of preforms largely depend on the pros and cons of PET materials. Choose materials that are easy to inflate and shape, and formulate a reasonable preform molding process. 90 wide mouth preform mold production

Factors for forming PET preform mold plastic parts: The length of the mandrel in the PET preform mold is generally 10:1. Because the parison is subjected to greater injection pressure during the mold filling process, if the ratio of its length is large, it will cause the mandrel to bend larger and easily cause uneven wall thickness distribution of the parison. The height of the mandrel is also referenced according to the specific height of the parison. When producing these parisons with the correct size, the temperature should be stabilized at about 145 degrees Celsius to produce highly transparent plastic parts. The melt temperature of the preform is also the main factor in its forming. For the PET mold, the temperature in the equipment has a very large impact, so the temperature of the barrel must be increased to ensure the temperature of the PET melt. When the temperature of the barrel is 280 degrees Celsius, the temperature of its melt must be 290 degrees Celsius, so as to ensure that the produced plastic parts have high transparency. The PET preform, a manufacturer of milk preform molds, is a plastic product processed by injection molding. It is impermeable and insulating. It is generally used for the storage and transportation of some important liquid objects.

The preform mold requires less heat for preforms that have been heated for secondary use or preforms whose storage time exceeds the standard, and the pre-blowing pressure can also be appropriately reduced. 90 wide mouth preform mold production

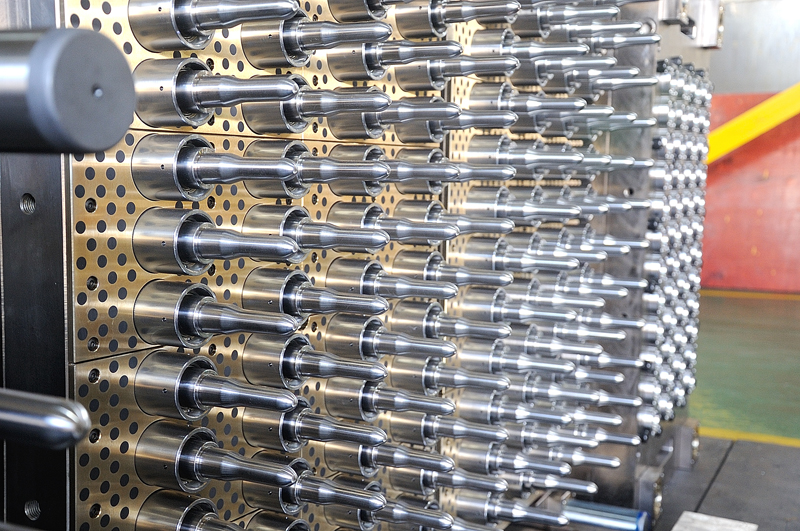

As we all know, the injection molding process of PET bottle cap mold is one of the very important technical processes in plastic processing. For PET plastic bottles, blow molding mold manufacturers will use blow molding to make and process in most cases, but the injection molding process Especially for the unique processing advantages, for the injection molding of PET preform molds, technicians need to consider many factors. PET preform molds are generally multi-cavity molds. If SIDEL molds can achieve uniformity and compatibility, it is the high-precision standard for multi-cavity molds. Preform molds are generally relatively slender, because the flow channel performance of PET is not very good, so it is necessary to suspend a harder steel material. 90 wide mouth preform mold production

TAOYUAN MOULD is committed to machinery and industry equipment, and realizes the pursuit of high-quality management with technological innovation. TAOYUAN MOULD is used for manufacturing and sales of molds and plastic products; sales of mechanical equipment and spare parts; import and export of goods and technology. We develop needle valve preform molds, various pipe fitting molds, bottle blowing molds, etc. Adopt the world's advanced CAD/UG/VT/ST design software, with outstanding experts and quality production equipment. One of the companies that provide customers with good preform molds, TAOYUAN MOULD always influences and drives the team's success with a down-to-earth spirit and a belief in winning. TANG TAO, the founder of TAOYUAN MOULD, always pays attention to customers, innovates technology, and wholeheartedly provides customers with good services.